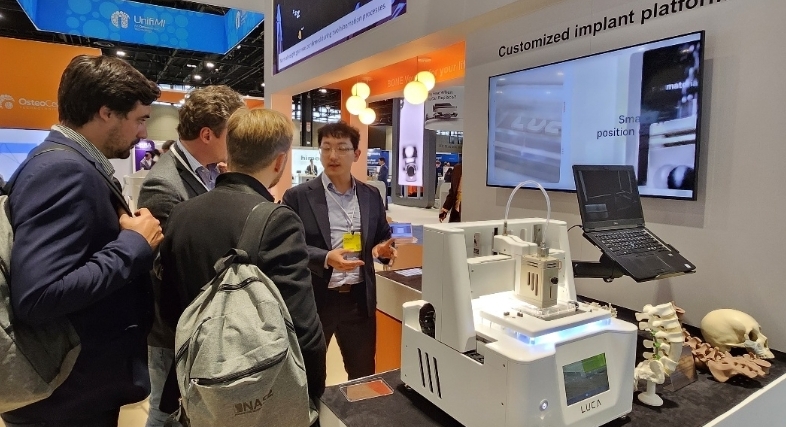

CGBIO (representative director Hyun Seung Yu), a company specializing in bio-regenerative medicine, announced on the 24th that they participated in NASS (North American Spine Society) 2022, a North American spine society, unveiling its next-generation height expandable cage, ‘Excender’ and the ‘PSI (Patient Specific Implants) Platform’ the system for manufacturing and supplying one-stop patient-specific 3D implants.

NASS 2022, held in Chicago, USA, from the 12th to the 15th, is the world’s largest and most prestigious international society in the field of the spine that has been held every year since the first society in 1985.

CGBIO ran an exhibition promotion booth at NASS 2022 and held meetings with various spinal implant companies. They had in-depth business discussions on the Excender and PSI platforms with several global companies in Europe, the Middle East, and South America, including Precision Spine and Globus, representative spinal implant companies in the United States.

Excender is a next-generation height expandable cage that applies the way to expand inside the body to facilitate surgery in narrow spinal disc spaces. In the case of the existing height expandable cages shown, they are all-around open cages, difficult to preserve the bone substitute perfectly due to the possibility of contents leaking. However, since the Excender has a shielding structure, there is no leaking of the bone substitute, and it can show a higher bone union rate.

The PSI (Patient Specific Implant) platform is a one-stop manufacturing and supply system for the patient-tailored 3D implant. By uploading the CT data provided by the hospital to the CGBIO Cloud, the experts at the CGBIO Design Center complete implant modeling and provide the data to print centers around the world to print implants. All this process will be completed within 2 weeks.

In particular, since CGBIO operates a design center separately, there is no need for professional personnel to carry out design work locally, so the client only needs to operate the output center. In addition, the initial investment and operating costs were significantly reduced through the use of artificial intelligence (AI) and process automation, which was well responded from many companies and hospital officials in the field.

Hyun Seung Yu, the representative director said, “At NASS 2022, the world’s largest spine society, CGBIO introduced a new platform and could confirm its appearance as a global trend leader beyond the fast follower, which is the limit of Korean companies.” “We will strive to become a global medical device trend leader based on continuous research and development,” he said.

▲NASS 2022