The goal of CGBIO Co., Ltd. (CEO Hyun-Seung Yoo), a company specializing in bio-regenerative medicine, was recently announced on the 10th by ReMDO (RegenMed Development Organization, CTO Joshua Hunsberger). The company will cooperate with WFRIM, Wake Forest Institute for Regenerative Medicine for the development of global research on regenerative medicine.

ReMDO is a non-profit agency with a mission to conduct R&D on treatments for patients through the science of regenerative medicine by connecting academia, industry, and government agencies. They have a relationship with world-class regenerative medicine companies.

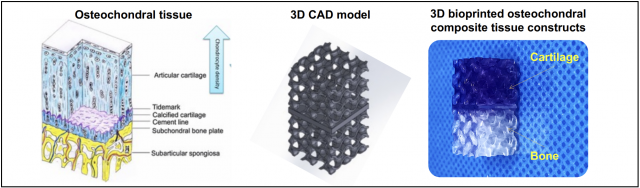

WFIRM, a US regenerative medicine research institute, is internationally recognized in the field of regenerative medicine research. Its research team, led by professor Sang-Jin Lee and known as the foreman of 3D bioprinting, will conduct a joint research with CGBio on treatment through regenerative medicine by 3D printing a composite structure of bone and cartilage.

Professor Lee’s research team won with tissue constructs using bioprinting during the Vascular Tissue Challenge last June, a competition to create tissues with artificial blood vessels, which is a part of NASA’s Centennial Challenges to seek ideas for space exploration.

According to a report of “Changes in Life-Cycle Consumption in an Aging Economy Population” released by the Bank of Korea last March, the population over 65 years old in Korea will reach 20% in 2025, making Korea enter a super-aged society. Because of this, academia and industry is consistently focusing on developing treatment for patients with age-related joint damage.

The current research on treatment for joints is mainly conducted to develop the treatment for bone and cartilage separately. However, there have been a lot of difficulties in treatment as bone and cartilage stay close, making it hard to distinguish clearly. In this regard, many experts say that treating the borderline between bone and cartilage together is essential for an effective joint treatment.

CGBio plans to provide its multi-channel 3D bioprinter with high precision which is self-manufactured to print a composite structure of bone and cartilage and bio materials such as glass-ceramics (BGS-7), osteogenesis protein (rhBMP-2), and transforming growth factor (TGF-β3) to Professor Lee’s research team. The team will produce 3D-printed scaffolds that can make bone and cartilage cells grow together and conduct research on technology for differentiating bone and cartilage and the regulation of it.

The research on bio-composite structure is significant in not only overcoming a technological limit of current treatment which is a joint replacement, but also shifting into a fundamental treatment paradigm, namely ‘regeneration of joints’.

Current joint treatment, arthroplasty or joint replacement surgery is an operation to replace a damaged joint with an artificial joint, but this could be followed by occurrences of nonunion, malunion or infection after the surgery. For this reason, treatment to regenerate joints similar to the original state is required, but research on this has a long way to go.

CEO Hyun-Seung Yu said “I look forward to enhancing the quality of life for patients with joint damage by paving the way towards joint regeneration treatment through this research. Based on the cooperation with WFIRM, which has world-class research capabilities, the company will spare no efforts to play a leading role in the global market for joint treatment by developing differentiated products to overcome limits that existing treatment has”.